The introduction of silicon for certain watch components

This year marks a historic turning point with the introduction of a new material in watchmaking: silicon. Non-magnetic, lightweight and particularly resistant to corrosion and wear, the advantages of this material quickly won over the entire industry.

In 2006, Breguet has once again achieved a major breakthrough in horological technology with the introduction of various critical mechanical movement parts in silicon.

The planet’s second most common substance after oxygen, silicon is impervious to magnetic attraction and influence and, more important still, highly resistant to corrosion and wear. Lighter and harder than steel, it reduces inertia, requires no lubricant and provides far greater geometric freedom, i.e. opportunities to turn out new and complex shapes.

In the watchmaking field, the properties of silicon also prove mechanically useful for certain movement parts. The production method for silicon components makes it possible to create extremely complex shapes while ensuring extreme precision.

Research on silicon began as early as 2006, with the first applications in Breguet modules. The Classique 5177 watch is since then equipped with an escape-wheel and a lever in silicon, while the Classique 5197 and 5837 watches feature a silicon version for three components : the escape-wheel, the lever and the flat balance spring.

The watchmakers of the Manufacture Breguet have worked on other properties of silicon which imply that parts may be accurately machined and are distinctly lighter. This led them to develop the Type XXII 10 Hz with silicon balance spring, lever and escape-wheel, which became the first and only series-made mechanical chronograph with a frequency raised to 10 Hz or 72,000 vibrations per hour, capable of marking off 20ths of a second. The lowering of the mass of these central components of the watch was a critical stepping stone to raising the frequency to the revolutionary plateau of 72,000 beats per hour.

For two hundred years, watch makers have struggled to minimize the effect of temperature changes on the running of watches. With the change to silicon for the spiral, new temperature effect studies were called for. Breguet’s answer, protected by a patent, is a special thermal oxidation process for the silicon.

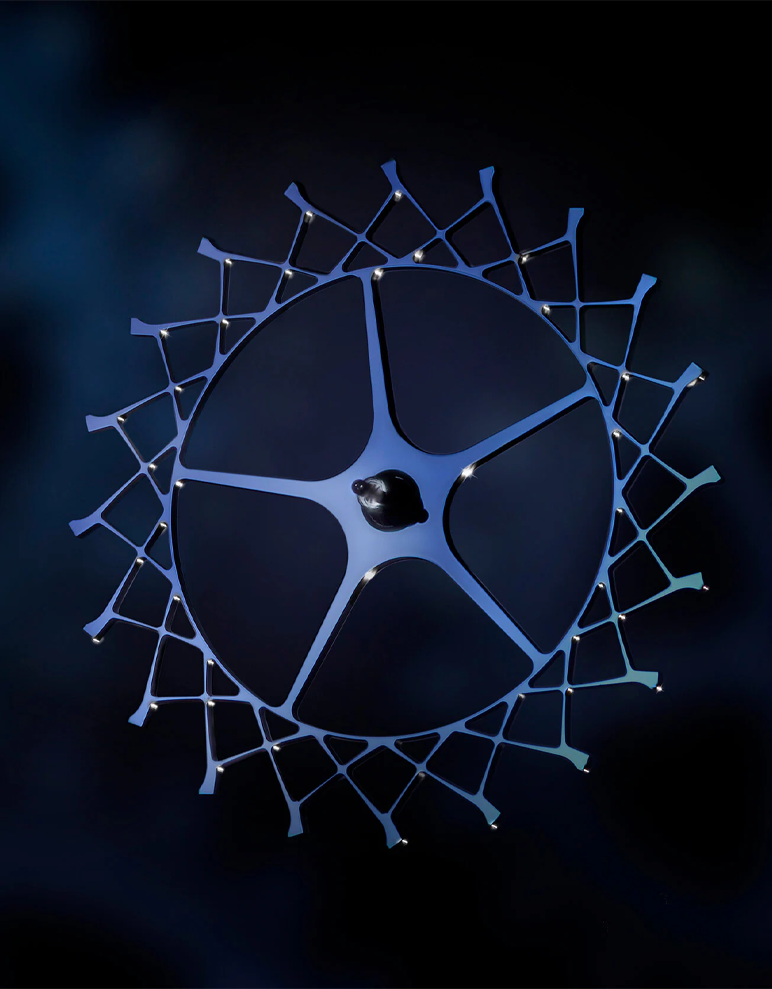

Escape-wheel and lever in silicon

More is involved, however, than mere replacement of components which are customarily constructed using Nivarox (for the spiral) and steel (for the anchor and escapement wheel) with new material. New innovations were developed in the shapes of the escape wheel and anchor to lower their mass (and consequently, inertia). The use of silicon confers yet another advantage. Ordinary escapement wheels require lubrication to prevent wear.

Silicon’s natural wear resistance eliminates the need for lubrication of the outer surface of the wheel, which is particularly important at a high frequency. The use of balance springs and escape-wheels in silicon, boasting anti-magnetic properties, as well as a better understanding of the way in which magnetic fields affect the inside of the movement, served to envisage the use of magnets inside the watch mechanism in order to improve its performances.